From Leak to Road-Ready

Breakdowns don’t tend to RSVP. They’re the surprise guest that just shows up. But some truck problems give you warning before things go sideways. That was the case when we got a call from 3 Nieces Trucking about their 1999 Kenworth W900. It had a head gasket leak that showed up a few months earlier. After a diagnosis and some discussion, we all agreed: schedule it, plan for it, and get it fixed right. That’s the kind of approach we like. It brought that truck into our Kylertown truck repair shop with time to do things properly.

A Failing Head Gasket Doesn’t Hide for Long

When head gaskets start to fail, they don’t usually go quietly. You might see white smoke, notice coolant loss, or just feel the power drop off. This Kenworth had logged serious miles—north of 300,000—and that’s the range where trouble starts showing up.

During our initial inspection, we confirmed what we suspected: the gasket had failed between the block and the cylinder head. That’s a pressure point, and when it gives, it can lead to coolant mixing with oil or compression loss. Either one is bad news if you let it ride too long.

The Breakdown Before the Breakdown

Think of the head gasket like a dam. It’s supposed to hold back pressure, oil, and coolant in their own lanes. When that seal gives out, the whole system starts to unravel. Here’s what usually leads to this kind of failure:

- High mileage without regular maintenance

- Excessive engine heat or overheating episodes

- Poor quality coolant or contaminated fluids

- Heavy-duty hauling without enough cooling support

We’ve seen plenty of engines fall apart because this one gasket went ignored too long. That wasn’t going to happen here.

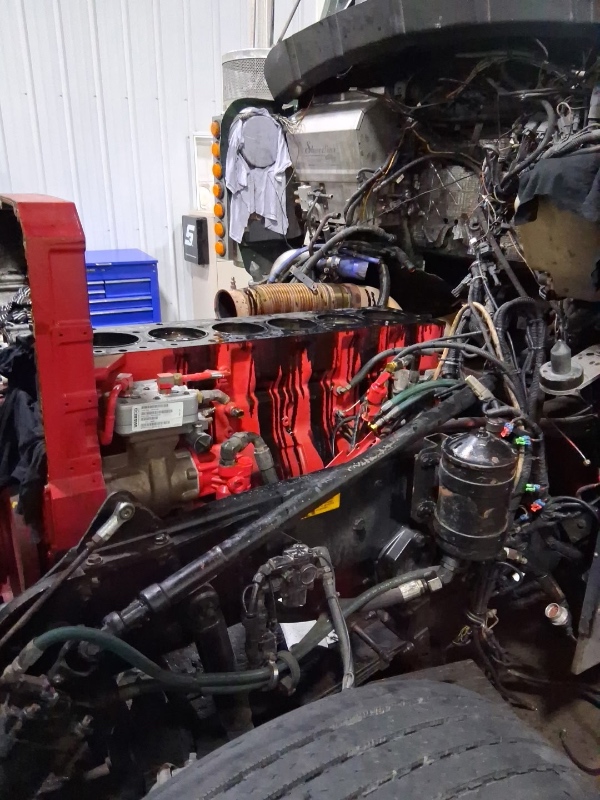

Step by Step, Bolt by Bolt

When we started the job, everything went smoothly. No surprises, no hidden issues. That’s the kind of job we like. We drained all the fluids, unhooked the manifolds, lines, and sensors, and pulled the head clean. We even ran a thread chaser into the bolt holes to make sure nothing would compromise the seal on the new install.

Here’s how we knocked it out:

- Removed the radiator, CAC, and condenser

- Pulled the head using a forklift and picker

- Cleaned and inspected the head surface and block deck

- Verified liner height to ensure future seal integrity

- Installed new gaskets and reassembled all components

- Recharged the A/C with 4 lbs. of freon after reconnecting the condenser

We ran the truck up to operating temperature and took it for a test drive. Everything checked out. Three days from pull-in to rollout. That’s what a solid Kylertown truck repair looks like.

Maintenance Isn’t Just About Fixing What’s Broken

We get it—trucks run hard, and schedules are tight. But if you keep kicking the can down the road, you’re gonna end up on the side of it. One thing we always tell our customers: use your pre-trip inspections. A few extra minutes with a flashlight can catch the early signs of leaks, drops in fluid levels, or buildup around the head. It’s not about being paranoid—it’s about being ready.

Simple habits help avoid big problems:

- Monitor mileage and stick to scheduled maintenance

- Check coolant levels and condition regularly

- Watch for exhaust smoke that changes color

- Keep an eye on temperature gauges under heavy load

Head Gasket Frequently Asked Questions

What are the signs of a failing head gasket on a semi-truck?

A: White exhaust smoke, coolant loss, milky oil, overheating, and reduced power are common red flags. Drivers should stop and schedule repairs before major engine damage occurs.

Can a head gasket be repaired on a high-mileage truck like a Kenworth W900?

A: Yes. With proper inspection, resurfacing, and sealing, a gasket repair can restore compression and performance, even past 300,000 miles.

How long does a head gasket repair take on a Class 8 truck?

A: Most commercial truck head gasket replacements take 2–4 days depending on teardown complexity, parts, and any secondary issues discovered during inspection.

What causes a head gasket to fail in diesel engines?

A: High mileage, overheating, improper coolant maintenance, and heavy hauling that stresses the cooling system are frequent contributors.

Is it safe to keep driving with a head gasket leak?

A: No. Continuing to drive can lead to coolant-oil contamination, warped components, and complete engine failure—often turning a repair into a full rebuild.

Do you offer head gasket repair and diagnostics near Kylertown, PA?

A: Yes. Bigler Boyz Truck Repair provides complete diesel engine diagnostics, cylinder head removal, and gasket replacement services for commercial trucks in Kylertown and surrounding areas.

What maintenance helps prevent head gasket issues on heavy-duty trucks?

A: Regular coolant checks, temperature monitoring under load, and scheduled inspections around 250K–300K miles help catch gasket issues before they become expensive failures.

Bigler Boyz Is the Name Locals Trust for Kylertown Truck Repair

Not every repair shop is set up to handle a job like this. Pulling a cylinder head off a W900 isn’t something you rush. You need the right tools, the right space, and the right mindset. We’ve been doing Kylertown truck repair long enough to know that cutting corners comes back to bite you. That’s why every gasket we install gets checked during our Kylertown truck repair service, every bolt gets torqued, and every truck gets test-driven.

At Bigler Boyz Truck Repair, we take Kylertown truck repair situations like this one seriously. When 3 Nieces Trucking brought in their Kenworth, they didn’t just need a gasket replaced. They needed that truck back on the road, reliable and road-ready. That’s exactly what we gave them—with no guesswork and no shortcuts.

When you need Kylertown truck repair, you want the job done right the first time. And that’s how we work. Every time.